2025 BMES Annual Meeting Post Show Wrap-Up

Bridging Healthcare Gaps Through Biomedical Engineering The Biomedical Engineering Society (BMES) is excited to share the official 2025 Annual...

BMES serves as the lead society and professional home for biomedical engineers and bioengineers. BMES membership has grown to over 6,700 members, with more than 110+ BMES Student Chapters, three Special Interest Groups (SIGs), and four professional journals.

Welcome to the BMES Hub, a cutting-edge collaborative platform created to connect members, foster innovation, and facilitate conversations within the biomedical engineering community.

Discover all of the ways that you can boost your presence and ROI at the 2024 BMES Annual Meeting. Browse a range of on-site and digital promotional opportunities designed to suit any goal or budget that will provide maximum impact.

1 min read

BMES 03/02/2020

Biomedical engineers at the UConn School of Dental Medicine have developed a handheld 3D bioprinter that could change the way musculoskeletal surgical procedures are performed, the university reports.

The bioprinter, developed by Dr. Ali Tamayol, associate professor in the School of Dental Medicine biomedical engineering department, enables surgeons to deposit scaffolds—or materials to help support cellular and tissue growth—directly into the defect sites within weakened skeletal muscles, according to the article. Tamayol is a BMES member.

Tamayol's research was recently published in the American Chemical Society journal.

“The printer is robust and allows proper filling of the cavity with fibrillar scaffolds in which fibers resemble the architecture of the native tissue,” Tamayol said in the article.

The scaffolds from the bioprinter adhere precisely to the surrounding tissues of the injury and mimic the properties of the existing tissue— eliminating the need for any suturing.

Current methods for reconstructive surgery have been largely inadequate in treating volumetric muscle loss, according to the article. As a result, 3D printing technology has emerged as an up and coming solution to help reconstruct muscle.

Currently there is no good solution for patients who suffer volumetric muscle loss, according to the article. A customizable, printed gel establishes the foundation for a new treatment paradigm and can improve the care of trauma patients.

Read more HERE.

Bridging Healthcare Gaps Through Biomedical Engineering The Biomedical Engineering Society (BMES) is excited to share the official 2025 Annual...

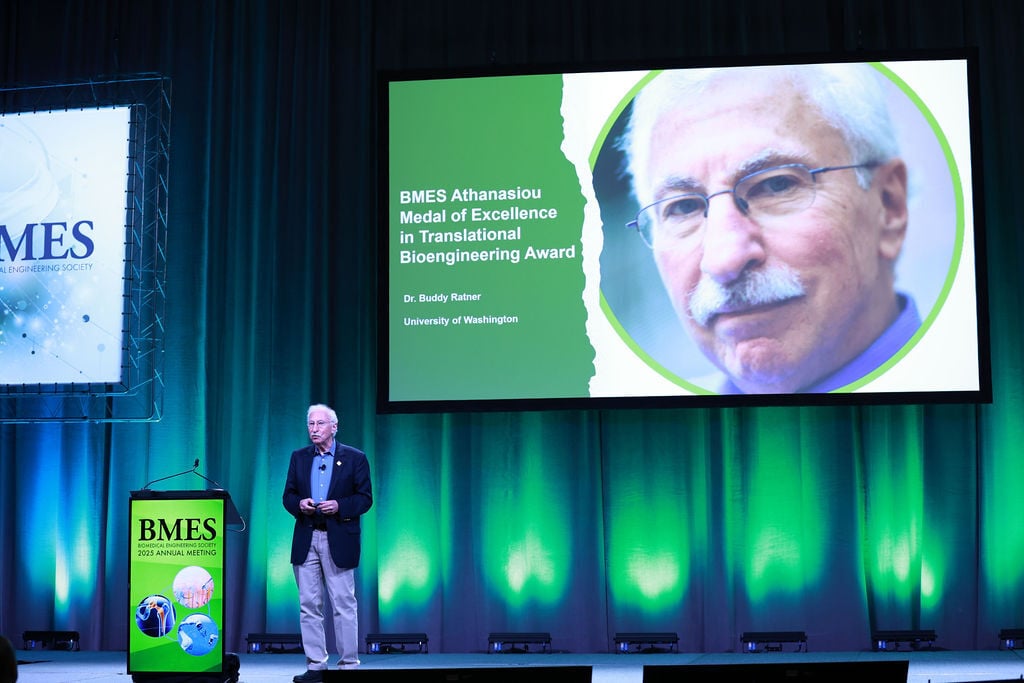

For Buddy Ratner, BMES Member and Professor of Bioengineering and Chemical Engineering at the University of Washington, translational bioengineering...

Two new Editors-in-Chief were selected for two prestigious Society journals: Keefe Manning, was named the new Editor-in-Chief of the Cardiovascular...

1 min read

BMES has signed onto a letter with nearly 350 member organizations representing patients, clinicians, scientists, educators, academic institutions,...

The Biomedical Engineering Society (BMES) is devoted to developing and utilizing biomedical engineering to improve health and well-being for all...